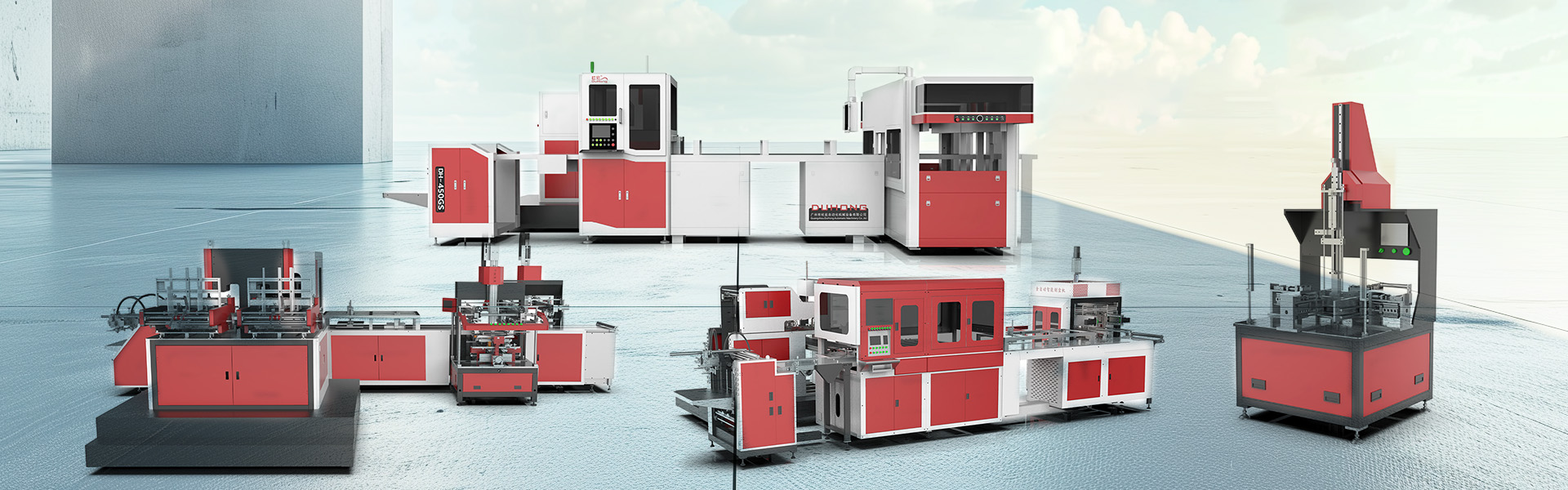

Full-automatic Intelligent High-speed Box Making Machine

| Availability: | |

|---|---|

| Quantity: | |

This machine uses an imported PLC and touchscreen Human-Machine Interface (HMI) control system, along with a visual positioning system, to fully automate processes such as paper feeding, gluing, greyboard insertion, corner pasting, positioning, box dragging, edge wrapping, ear folding, and final forming.

Equipment Features:

① Suitable for automatic production of various hard boxes with lids and tops. | ② Full computer function parameter settings and fault display and shutdown function. |

③ Automatic suction and feeding of facial paper and grayboard paper. | ④ Equipped with glue preheating and timed heating functions. |

⑤ Heating for corner pasting machine is controlled independently via the human-machine interface. | ⑥ The entire machine is controlled by a PLC and a touchscreen human-machine interface. |

⑦ Error correction positioning system (positioning error ±0.1mm) | ⑧ Equipped with an automatic paper retrieval mechanism for the forming section. |

⑨ Can be modified to produce various shaped lids and bases according to customer requirements (optional). | ⑩ Automatic glue viscosity control system (optional); (see notes for details). |

? Single-station forming mechanism. | ? Two-layer edge sealing for long and short sides. |

? Fixed pull gauge. | ? Servo-driven bottom mold forming mechanism. |

? The box ejection direction is at a 90° angle to the main conveyor belt. | |

The DH-450GS automatic rigid box forming machine is a fully automatic equipment designed for simultaneous forming of the base and lid, automatic paper feeding, forming, edge folding, corner pasting, and box ejection. It is specifically tailored for mass production of various types of hard boxes with lids and bases, including shoe boxes, mobile phone boxes, toy boxes, cosmetic boxes, health supplement boxes, and more.

Product Description

Type | DH-450GS |

Paper size(max) | L600*W700mm |

Paper size(min) | L80*W130mm |

Paper Thickness | 100-400g/m² |

Cardboard Thickness | 0.8~3mm |

Finished Product(Carton)Size(max) | L500*W400*H120mm |

Finished Product(Carton)Size(min) | L65*W65*H12mm |

Fold-in edge size(Rmax) | 120mm |

Fold-in edge size(Rmin) | 10mm |

Positioning Accuracy | ±0.10mm |

Production Speed | 20-50pcs/min |

Total Power | 36kw/380v 3phase |

Production Operating Power | 26kw |

Auxiliary Power | 11kw |

Electric Power | 5.1kw |

Weight | 5560kg |

Mchine size(L*W*H) | 8350*5390*3400mm |

This data is intended as a rough reference; actual results may vary based on individual cases. | |

Remarks:

1. The finished Box Max. sizes are determined by paper size.

2. Either the Max. Sizes or the Min. Sizes can not be fulfilled on the same box.

3. The production speed of the rigid box machine is determined by the box size, the paper and the grey board materials.

4. Seller doesn't provide air compressor. (8atm=0.8MPa, 7.5kW compressor is needed).

5. Specific box and paper can fulfill folding in depth above 20mm.