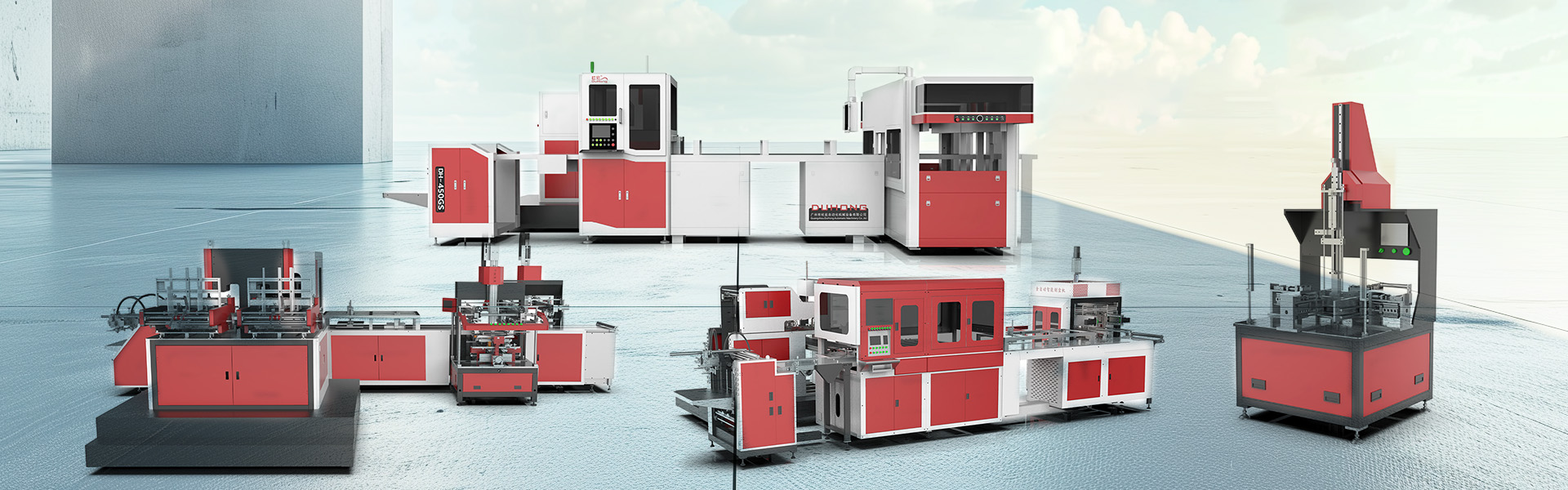

Equipment Features:

① Modular components in multifunctional automated smart box making | ② Energy-saving and environmentally friendly design |

③ Equipment is easy to operate | ④ High operational safety |

⑤ Easy machine maintenance | ⑥ Fully-automatic completion of grayboard cornering |

Product Description

Type | DH-4045T |

Finished Product(Carton) size(max) | L530*W470*H120mm |

Finished Product(Carton) size(min) | L65*W65*H12mm |

Gray Board Thickness | 0.8~3mm |

Unfolded size of corner board(Cmax) | 520mm |

Unfolded size of corner board(Cmin) | 60mm |

Unfolded size of corner board(Dmax) | 620mm |

Unfolded size of corner board(Dmin) | 85mm |

Leather Case(Linde) size(Pmax) | 1080*570mm |

Leather Case(Linde) size(Pmin) | 80*100mm |

Positioning Accuracy | ±0.10mm |

Electric Power | 4.5kw |

Paper Thickness | 100-400g/m2 |

Production Speed | 45pcs/min |

Total Power | 4kw/220v 1phase |

Electric Power | 600w |

Weight | 1050kg |

Machine size(L*W*H) | 2205*2020*2800mm |

This data is intended as a rough reference; actual results may vary based on individual cases. | |

Remarks:

1. The finished Box Max. sizes are determined by paper size.

2. Either the Max. Sizes or the Min. Sizes can not be fulfilled on the same box.

3. The production speed of the rigid box machine is determined by the box size, the paper and the grey board materials.

4. Seller doesn't provide air compressor. (8atm=0.8MPa, 7.5kW compressor is needed).

5. Specific box and paper can fulfill folding in depth above 20mm.